Search

The focus is shifting toward synthetic long-drain engine oils

Ravi Chawla, MD and CEO, Gulf Oil Lubricants India, speaks on how demand for lubricants and oils is evolving in the construction, mining, and off-highway sectors over the next 12 to 18 months.

Mobil drives mining’s digital evolution with future-ready lubrication

Vasanth Thangavelu, General Manager – Brand Marketing South AP, ExxonMobil Lubricants, shared how the brand continues to strengthen its commitment to India’s mining sector through advanced lubrication solutions, digital tools, and technical services designed to help operators achieve superior reliability and performance.

Mobil drives mining’s digital evolution with future-ready lubrication

Vasanth Thangavelu, General Manager – Brand Marketing South AP, ExxonMobil Lubricants, shared how the brand continues to strengthen its commitment to India’s mining sector through advanced lubrication solutions, digital tools, and technical services designed to help operators achieve superior reliability and performance.

Unearthing Potential

Today, mining is a $1 trillion industry, providing materials for everything from the energy sector to the commercial goods market.

Fighting Fire with Innovation

As the coal mining industry continues its quest for enhanced safety measures and environmental consciousness, integrating fire resistant hydraulic fluids emerges as a pioneering solution with the potential to mitigate fire hazards and elevate operational security to unprecedented heights. The author explains the need for fire resistant hydraulic fluids and their importance within the coal mining industry.

Lubricants play a crucial role in equipment efficiency: V. Maloo, ENSO

Vaibhav Maloo, Managing Director, ENSO Group, speaks on the primary factors that construction equipment customers prioritise when selecting lubricants.

2030 Goal: 250,000 Excavators!

India aims to increase its annual production from approximately 85,000 units to 250,000 units by 2030, driven by infrastructure investments in roads, railways, and mining

Driving Dynamics

Hydraulic motors are integral to the driving dynamics of construction equipment, providing the necessary power, precision, and control for a wide range of applications.

The mineral’s demand is likely to increase by 3 per cent

Kirity Kumar, Business Segment Manager – Operating Solutions, Quaker Houghton, speaks on the types of products manufactured by the company for mining and other related industries.

Connecting Machinery with Efficiency

Essential for ensuring the safe and efficient operation of construction machinery like excavators, loaders, bulldozers, cranes, etc., hydraulic hoses play a crucial role in various equipment.

The Mining Boom

India's increasing coal projects drive a surge in mining equipment demand!

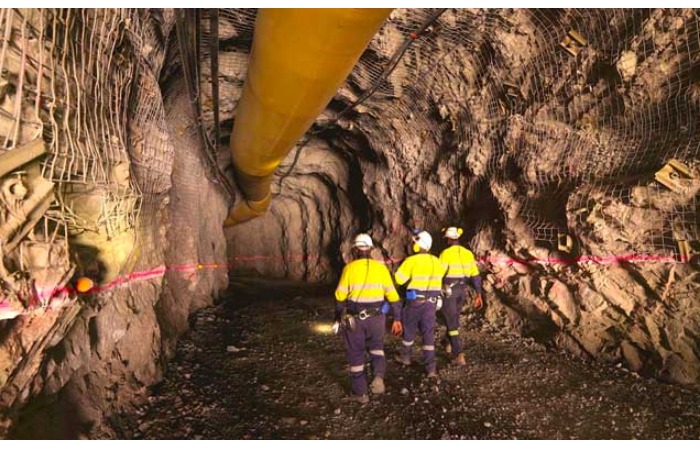

Navigating the Depths

How IIoT is enhancing safety and efficiency in underground mining.

Powering Machines

Automation and industrialisation are major drivers of demand for hydraulic motors in India.

We have fire-resistant hydraulic fluids for the mining segment

Tridib Majumder, Managing Director, Quaker Houghton India, speaks on the growth of the mining industry in India, and key digital features and solutions offered by the company.

Mining the Future

With prospects in both surface mining and underground mining, the Indian market for mining equipment appears to have a bright future.

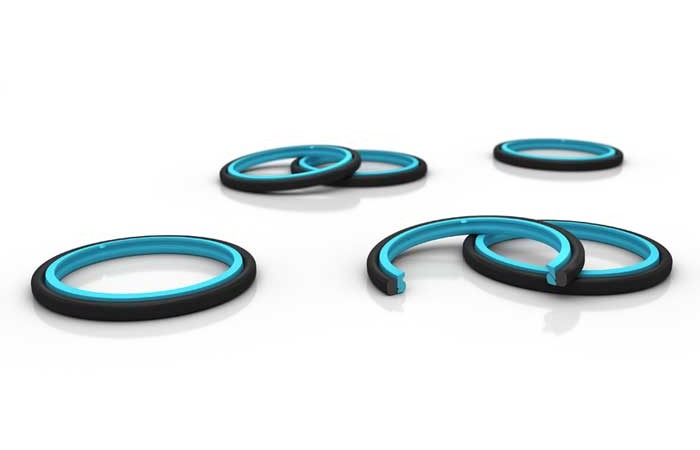

Beating the friction

Trelleborg’s Lubrication Management principles offer improved lifetime and performance across the whole sealing system.

fpsi conference on fluid power industry

The series of FPSI meetings held in Bengaluru for the fluid power fraternity comprising hydraulic, pneumatic and mechatronic industries, discussed and deliberated the key market trends and industry initiatives.

Facilitating smooth flow

Hose and fittings have their specific role and importance in hydraulic equipment and systems.

Couplings for Diesel Engines

KTR Couplings (I) Pvt Ltd, established in 1998 at Bhosari, Pune is a 100 per cent subsidiary of KTR Systems GmbH Germany, a well-known name worldwide for couplings and power transmission products.

GS Caltex showcases lube solutions

GS Caltex India showcased its Research and Development (R&D) capabilities, which is its core strength in developing product competitiveness for lubricants and polymers.

Lubricant industry is becoming more dynamic

Lubricants are a crucial component of achieving significant business value by helping reduce costs and improve equipment productivity. Praveen Nagpal, Chief Technology Officer, Shell Lubricants India, shares more on his company's major activities towards this.

Filters for efficiency

Hydraulic filters keep hydraulic fluids in an equipment free of contamination. Filter segment is developing further with a range of filters with new materials being introduced in the market.

OEMs are looking for more robust hoses

Eaton has a wide range of product offerings in fluid conveyance that meets the need for innovative products at optimised cost and NVH performance.

Effective Lubrication FOR Productivity

Infrastructure development and the demand for automotive products are major factors that are driving the growth of the metals and mining sector in India. To address the burgeoning demands of metal and steel, the Ministry of Steel aimed to increase the steel production capacity to 142.3 million tonne in 2017.

High performance rotary oil seal

Low-speed/high-torque (LSHT) hydraulic motors are one of the most cost-effective and dependable parts of a hydraulic system. Offering many advantages over a high-speed motor and gearbox speed reducer.

Ultimate reliability lubricants

OEMs have been under considerable pressure to offer engines that are more durable, more fuel efficient and produce less emissions than before.

Lubricants for Mining applications

Equipment working at mining sites need to perform reliably and efficiently, without major breakdown and other issues. Safe and efficient operation is imperative for mining equipment to increase productivity and safety in mining operations. Lubricants play a major role in this by minimising wear and tear of machinery parts and safeguard the equipment in the harshest conditions.

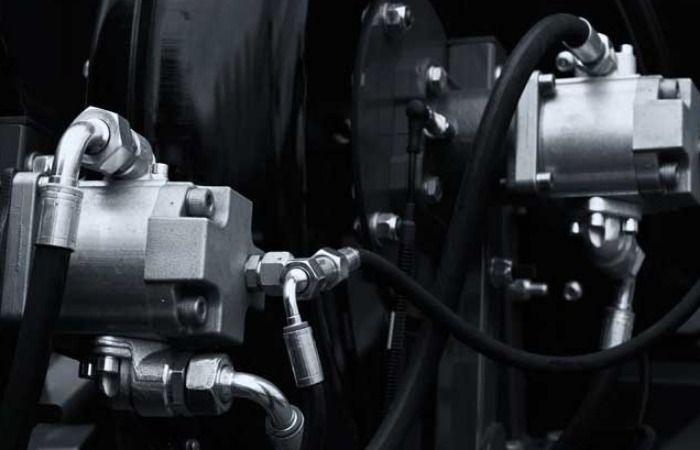

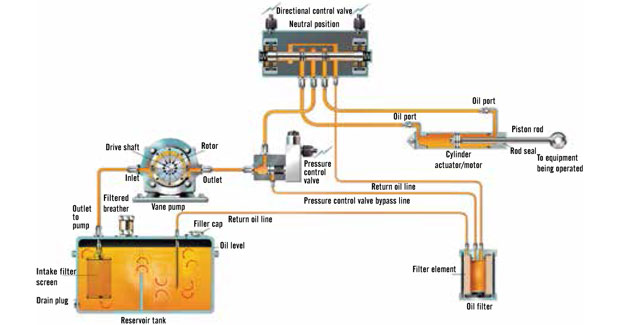

The Power of Hydraulics

Hydraulic power is generated through a combination of oil flow and pressure. Oil flow and pressure is created from a hydraulic pump and transmitted through hoses or tubes, via control valves, to the hydraulic motor or cylinder that will do the work.

Equipment Hydraulics

The evolution of construction machinery to what we see today is largely dependent on hydraulics. From relying on winches and cables, the construction/earthmoving equipment have come a long way to transform almost everything into hydraulically powered.

Hydraulic Hoses & Fittings

Hydraulic hose and fittings is one of the most important components in fluid power transmission. Selection of the right hose depends on various factors viz, operating pressure range, temperatures, abrasion resistance, and application and flow requirements. One should also consider the type of fluid conveyed and the application.

Optimising efficiency

With the construction, mining and infrastructure projects are growing faster, there is a growing demand for productive and efficient equipment in various projects. This will boost the demand for technologically superior lubricants to meet the industry needs.

Optimal Solutions

GS Caltex began base oil production in November 2007 with 16,000 BPSD capacity, but almost doubled its capacity by 2014. By using the latest cutting-edge hydro-cracking technology, the company produces high quality environment-friendly base oil, which satisfies challenging specifications of lubricant manufacturers.

Choosing the Right Hydraulic Fluids

When it comes to hydraulic fluids, the operating practices of yesterday are long gone. Today the pressure is on hydraulic systems. Hydraulic systems are expected to deliver optimum performance while operating under higher pressures, higher temperatures and tougher operating conditions

Shell Lubricants Launches Upgraded Tellus S2 Range

Shell Lubricants has launched Tellus S2 MX and Tellus S2 VX lubricants with new formulation, as part of the first leg of a global launch. Shell Lubricants has announced the launch of Shell Tellus S2 MX and Shell Tellus S2 VX - ?The Future of Hydraulic Oils? in India, at a function in Mumbai.

Lubricants: Smooth Sailing Ahead

With the government moving fast to meet the latest emission norms and OEMs making further improvement in design, the lubricants industry is set to witness a major revolution in product innovation.

Improving Efficiency

Mobil DTE 10 Excel 68 helped Samruddhi Industries improve hydraulic efficiency by 4.28 per cent, leading to annual savings of Rs 179,400. Hydraulic fluids with reduced environmental impact can provide sustainable solutions that support both environmental and economic goals.

IOC joins as Dynavis? licensee

Indian Oil Corporation Ltd (IOCL) has become Dynavis licensee to offer its customers hydraulic fluid formulated with Dynavis? technology.

Hydraulic System Care & Maintenance

Proper maintenance of hydraulic system and the hydraulic oil is crucial in maximising uptime and reducing maintenance cost. Hydraulic machines power the moving parts of many kinds industrial machines

Hydraulic Fluids with Reduced Enviro Impact

Hydraulic fluids with reduced environmental impact can provide sustainable solutions that support both environmental and economic goals, writes Shankar Karnik.

The Indian lubricants industry is expected to grow at 11.5 per cent

Synthetic lubricants in all applications are becoming more popular and widely used worldwide. While it is estimated that the current consumption of synthetic lubricants is about six per cent of the global lubricants consumption,

Choosing the Right

LubricantTwo important ways to help enhance the performance and durability of a company?s hydraulic systems are to use a high performance hydraulic fluid and to institute a proactive maintenance and oil analysis plan, says Rupinder Paintal.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com